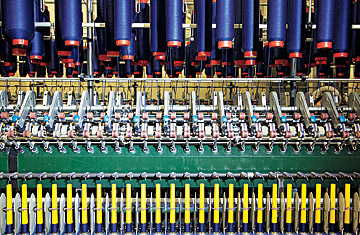

Ring spinners at the Patrick Yarns plant. The company specializes in not specializing.

(2 of 2)

In the company's oldest mill, located across town from the office, nearly a dozen different products are being made simultaneously. The process is complex, time-consuming and challenging. Nevertheless, manufacturing director Mitch Hensley says this specialized production process is worth the headache and is a big part of why the company has held its own in a tough manufacturing environment. "You cannot make this business work by just spinning commodity yarn, making commodity-type fabrics and competing only on price," says Hensley. "We take a market and hone it and make the highest-quality [yarn] at the lowest price. We're constantly trying to find the next new thing."

When describing exactly what he makes, Patrick cribs from a well-known ad campaign: "We don't make the products you buy. We make the products you buy better." Most yarn spinners, says Patrick, "will supply you with a list of yarns and say, 'Here's the prices.' We haven't tried to be everything to everybody in one market. We focus on partnering with our customers to engineer products and services to keep their product line innovative and profitable. Our approach is, 'Here are our capabilities. This is our expertise. Where can we be of assistance?'"

This strategy earned the yarnmaker a loyal customer in the protective-glove industry. Although that company's existing product line met cut-protection specs, low abrasion properties contributed to a short life span. Patrick Yarns developed a fiber that could double the cut protection and increase the abrasion resistance more than 300%. A minimal increase in production cost resulted in a longer-lasting, more malleable product that saved money over time. Patrick also creates earth-friendly products and operates the EarthSpan recycling program, which uses fibers from finished apparel or fabric and incorporates customers' unwanted textiles and scraps into engineered yarns or products that can then be sold in other markets.

Supplying fibers to so many different markets means the company is not reliant on any one segment for survival. Patrick has made production evolution and new designs the key components of his business model. Patrick Yarns holds nine patents and six trademarks in engineered yarns and those used for filtration. Natural fibers such as cotton and hemp end up in blankets and upholstery. Synthetic yarns have a variety of commercial uses, including in water filtration, as carpet backing and for automotive fan belts. The technical yarns developed from stainless steel, glass or Teflon find their way into fiber-optic cables and bushings used in spacecraft.

"The blanket-yarn market has disappeared, but we're developing a different yarn that will replace it," says Patrick. "This is unlike any recession we have experienced in most of our lifetimes, and it's cutting across virtually all segments of the economy. So we're doing everything possible to lessen the impact and create new avenues for business." It's a lesson that many in the U.S. textile business never learned.

INSIDE Preserving jobs--even if the alternative is losing them--can be demoralizing in certain ways too BARBARA KIVIAT ON SALARY REDUCTIONS