Manufacturers of everything from razor blades to footwear to drugs have for years been fighting a war with counterfeiters who sell cheap copies of their goods and diverters who infiltrate the distri-bution system. That the war is never-ending explains why you still see cosmetics made in Europe for the Hong Kong market showing up on the streets of Nairobi.

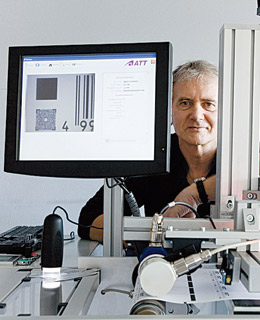

In 2006, ATT Advanced Track & Trace introduced a digitized marking-and-tracking method that allows manufacturers to verify whether their shipments are where they are supposed to be in real time. "What this does is allow brand owners to trace and track their goods — individually or as part of a larger shipment — and also have instant authentication that goods being sold as genuine really are," says Jean-Pierre Massicot, CEO of ATT, based in the Paris suburb Rueil-Malmaison. This is hugely important because customs authorities estimate that counterfeiting costs companies $250 billion to $400 billion a year. Counterfeit foodstuffs, pharmaceuticals and cosmetics, meanwhile, can carry serious health hazards for consumers — another reason ATT's breakthrough is valuable to manufacturers like GlaxoSmithKline and L'Oréal, which need to verify that goods sold under their name are authentic.

Central to that effort is ATT's Vector Seal technology, which stamps each product package with a unique, digitally created ID mark and traces it via scanners during the journey to the end user. Those square, pixilated codes are affixed in visible and hidden form on packages to prevent thieves from repacking bogus goods in the original containers. Because the codes are also impossible to reproduce in printed form without making them unreadable to scanners, the centrally stored Vector Seal codes ensure that counterfeiters can't produce "legitimate" brand-packaging ID for their knockoffs.